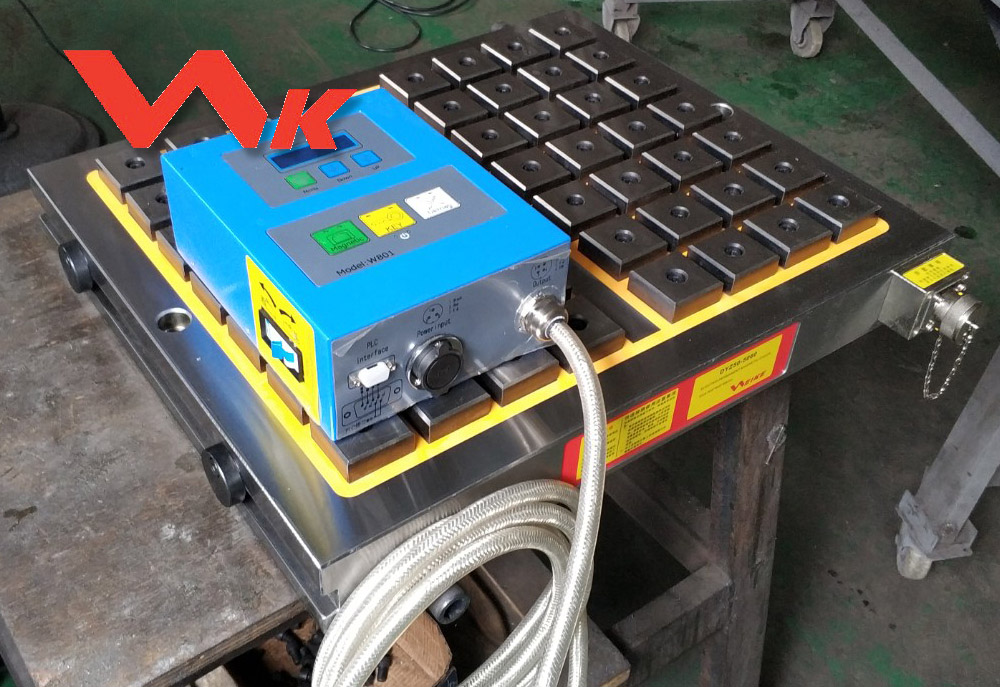

Electro permanent magnetic(EPM) milling chuck is the best magnetic clamping tool at present, which use electro pulse to (de)magnetize. It is safe and reliable when workpiece is clamped by magnetic chuck in mechanical processing."Magnetize and Demagnetize" time is less than 1 second, After magnetization, the magnetic chuck holds the magnetism permanently, and the chuck won't consume any energy at all during the whole machining process. It is widely used in CNC machining, milling and die manufacturing.

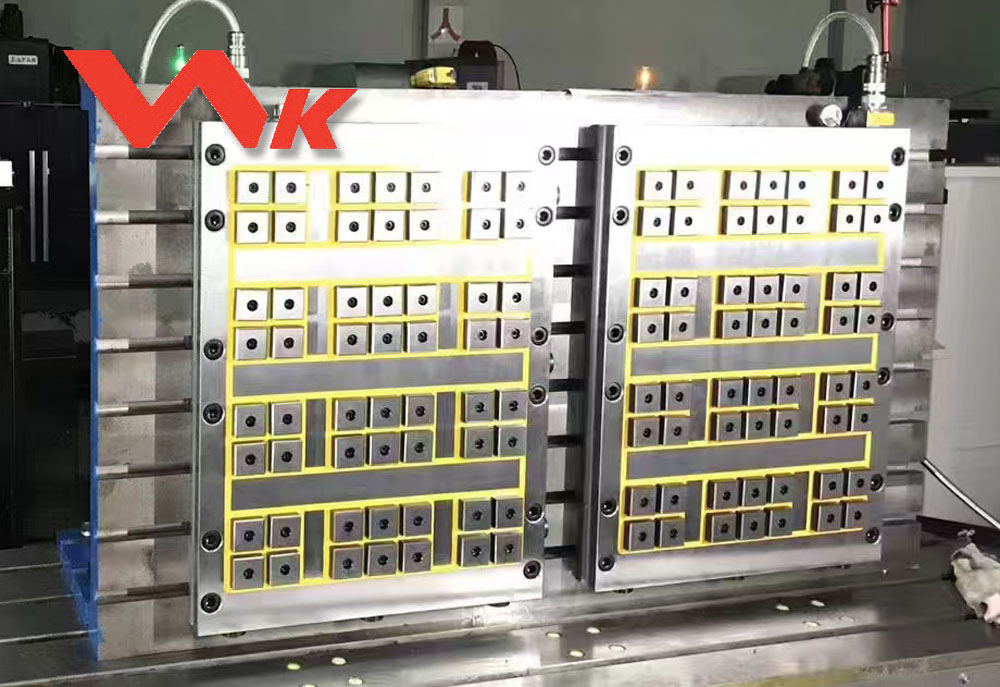

EPM chuck is applicable to various high precision CNC, CNC milling machine and etc. It is available to machine five sides, workpieces which is larger than working platform also can be held for machining.

EPM chuck is also applicable to clamp various components under heavy or high-speed milling in horizontal and vertical type; it can be for curving, irregular, difficult clamping, batch and particular workpieces. It is applicable to rough and finish machining.

Compared to conventional clamping tools. The electro permanent magnetic chuck can save more than 50% clamping operation time, increase working efficiency of labor and machine tool. Without changing machine tool or production line, it can reduce clamping workload greatly. Because of uniform force, workpiece won't be transformed, no shaking in mechanical processing. Extend service life of cutting tools..

Features

- Constant holding force can reach to 160~190N/cm², no need electricity when it is in magnetization status, won't lose holding force after power cut, no radiation of magnetic line, no heating phenomenon.

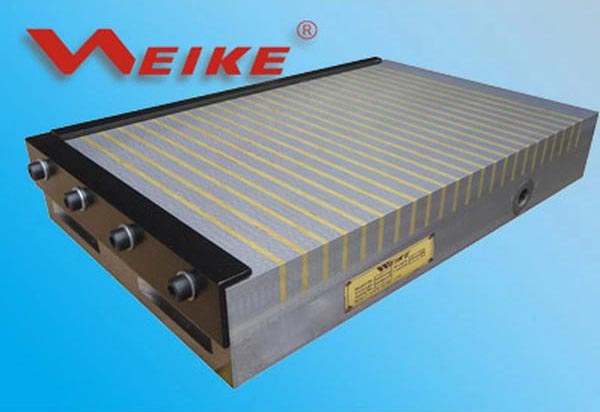

- Distinctive magnetic circuit, reasonable parameters, The EPM chuck body is milled integrally, powerful rigidity, no thermal deformation, high precision. attraction evenly. Strip, block and Deformed pole are available.

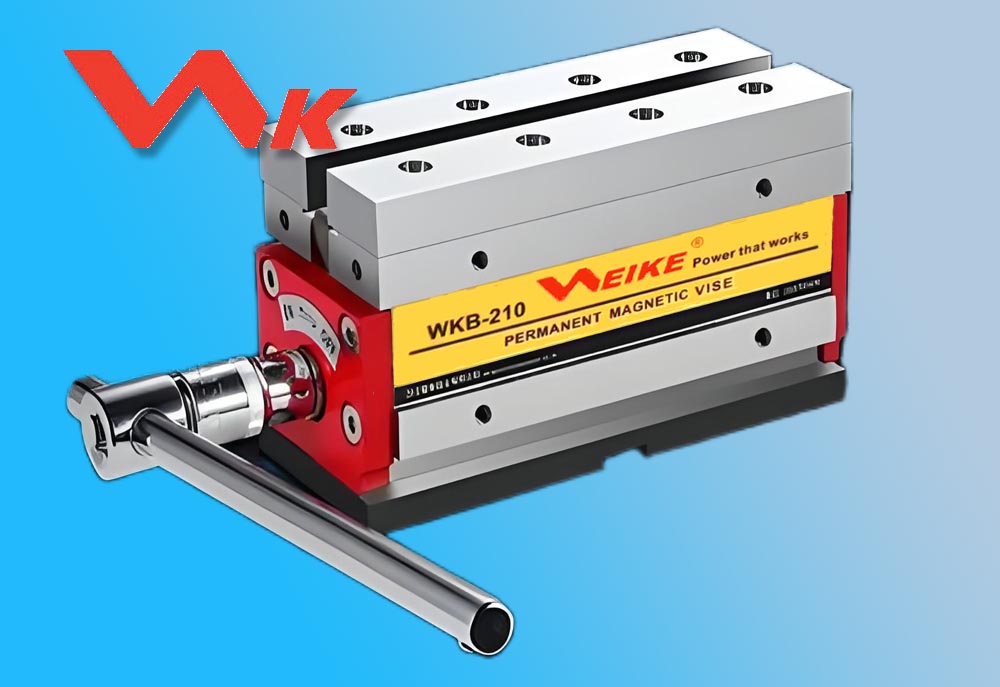

- Easy to operate, safe and reliable. Based on customers' requirement, we can make various electro permanent magnetic chuck of special performance and dimension.

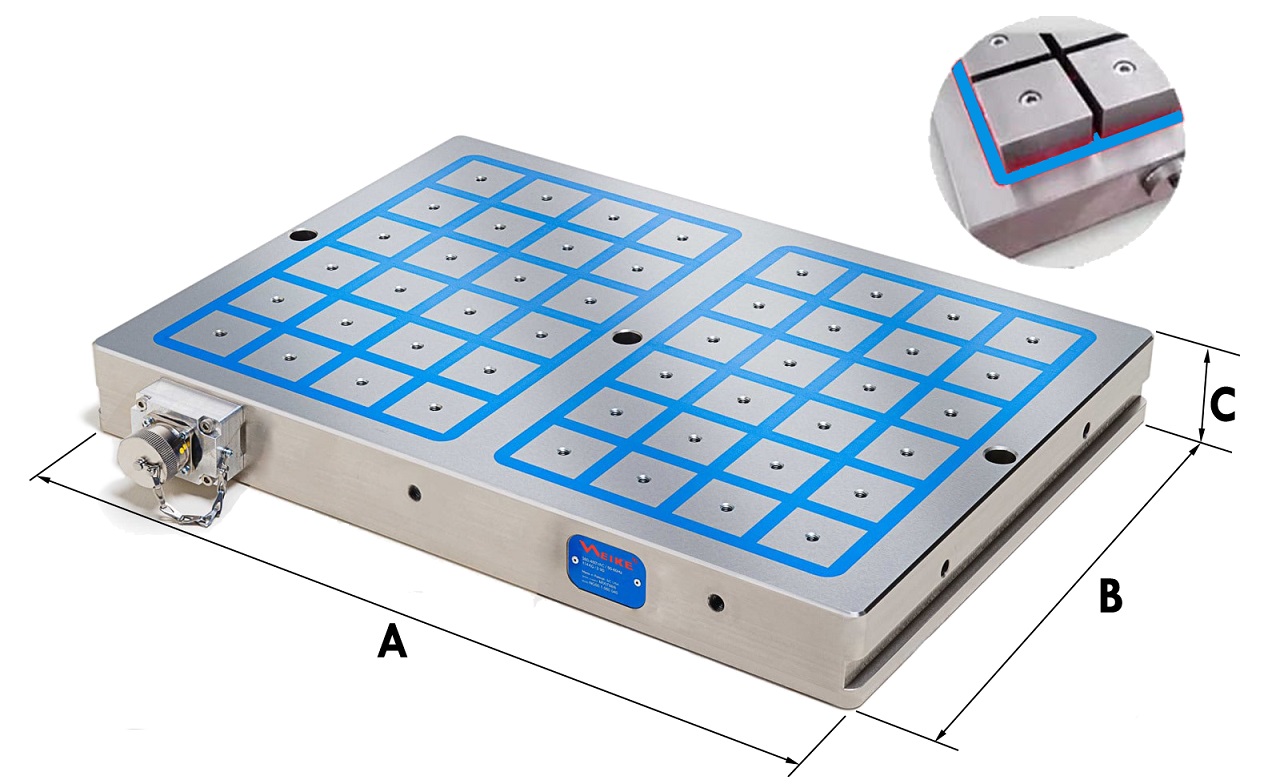

Basic Parameters

Pole size: 50x50mm or 70x70mm

Pole quantity: 2-200 pcs

Holding force of squre pole: 400 kg(50*50mm) 680 kg(70*70mm)

Parallelism: 0.002mm/100mm

Output Max Current: 50A

(De)magnetizing Time: 0.1~1.0s

Voltage: 3Ph 380V 50Hz or Customized

Height: 66mm(without padding block), 86mm(with padding block)

Models

Model |

Overall Size (mm) | Weight (kg) |

Pole Number | Pole Size | Model | Overall Size (mm) | Weight (kg) |

Pole Number | Pole Size | ||||

| A | B | C | A | B | C | ||||||||

| DYZ50-2443 | 240 | 430 | 66 | 52 | 3 x 6 = 18 | 50 x 50 mm | DYZ50-6060 | 600 | 600 | 66 | 180 | 8 x 8 = 64 | 50 x 50 mm |

| DYZ50-2459 | 240 | 590 | 66 | 72 | 3 x 8 = 24 | DYZ50-6081 | 600 | 810 | 66 | 252 | 9 x 11 = 99 | ||

| DYZ50-2481 | 240 | 810 | 66 | 99 | 3 x 11 = 33 | DYZ50-6099 | 600 | 990 | 66 | 301 | 9 x 14 = 126 | ||

| DYZ50-2499 | 240 | 990 | 66 | 120 | 3 x 14 = 42 | DYZ50-7581 | 755 | 810 | 66 | 310 | 11 x 11 = 121 | ||

| DYZ50-3031 | 300 | 310 | 66 | 47 | 4 x 4 = 16 | DYZ70-3042 | 300 | 420 | 69 | 64 | 3 x 4 = 12 | 70 x 70 mm | |

| DYZ50-3043 | 300 | 430 | 66 | 65 | 4 x 6 = 24 | DYZ70-3061 | 300 | 610 | 69 | 93 | 3 x 6 = 18 | ||

| DYZ50-3059 | 300 | 590 | 66 | 90 | 4 x 8 = 32 | DYZ70-3080 | 300 | 800 | 69 | 122 | 3 x 8 = 24 | ||

| DYZ50-3081 | 300 | 810 | 66 | 123 | 4 x 11 = 44 | DYZ70-3842 | 380 | 420 | 69 | 81 | 4 x 4 = 16 | ||

| DYZ50-3099 | 300 | 990 | 66 | 151 | 4 x 14 = 56 | DYZ70-3861 | 380 | 610 | 69 | 118 | 4 x 6 = 24 | ||

| DYZ50-4243 | 420 | 430 | 66 | 92 | 6 x 6 = 36 | DYZ70-3880 | 380 | 800 | 69 | 155 | 4 x 8 = 32 | ||

| DYZ50-4259 | 420 | 590 | 66 | 126 | 6 x 8 = 48 | DYZ70-5461 | 540 | 610 | 69 | 168 | 6 x 6 = 36 | ||

| DYZ50-4281 | 420 | 810 | 66 | 173 | 6 x 11 = 66 | DYZ70-5480 | 540 | 800 | 69 | 220 | 6 x 8 = 48 | ||

| DYZ50-4299 | 420 | 990 | 66 | 211 | 6 x 14 = 84 | DYZ70-5499 | 540 | 990 | 69 | 272 | 6 x 10 = 60 | ||

| DYZ50-4859 | 480 | 590 | 66 | 144 | 7 x 8 = 56 | DYZ70-6261 | 620 | 610 | 69 | 193 | 7 x 6 = 42 | ||

| DYZ50-4881 | 480 | 810 | 66 | 197 | 7 x 11 = 77 | DYZ70-6280 | 620 | 800 | 69 | 253 | 7 x 8 = 56 | ||

| DYZ50-4887 | 480 | 870 | 66 | 212 | 7 x 12 = 84 | DYZ70-6299 | 620 | 990 | 69 | 313 | 7 x 10 = 70 | ||

| DYZ50-4899 | 480 | 990 | 66 | 241 | 7 x 14 = 98 | ||||||||